Advanced Fasteners and Machining Techniques for Personalized Manufacturing

Grasping the Art of Bolts and Machining: Advancements and Ideal Practices

In the realm of industrial production and design, the proficiency of bolts and machining is a keystone of ensuring architectural honesty, functionality, and long life in different applications. Join us as we check out the newest innovations and delve right into the nuanced world of understanding bolts and machining, uncovering crucial understandings and methods that can raise your technique to engineering remedies.

Development of Fastening Technologies

Throughout the commercial transformation and right into the contemporary era, the evolution of securing technologies has been marked by constant innovations in efficiency and integrity. Bolts, such as screws, rivets, and screws, play a critical function in numerous markets, including automotive, aerospace, building, and electronic devices. The demand for more powerful, much more long lasting, and easier-to-install attachment remedies has actually driven technology in the field.

One considerable development has actually been the change towards accuracy machining techniques to develop fasteners with higher resistances and superior efficiency. This change has actually enabled producers to produce bolts that satisfy rigorous top quality criteria and deal boosted resistance to rust and tiredness.

Moreover, the introduction of innovative products, such as titanium alloys and composites, has reinvented the capacities of fasteners. Fasteners and Machining. These materials provide phenomenal strength-to-weight ratios, making them optimal for applications where reducing weight is critical without jeopardizing structural integrity

Improvements in Machining Approaches

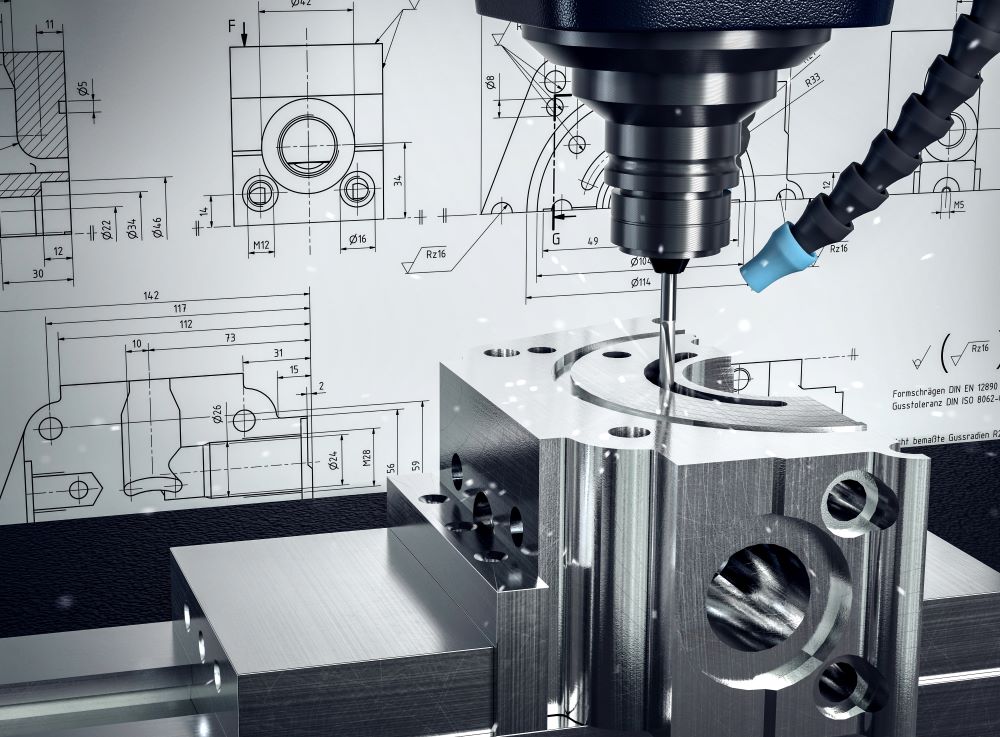

In the realm of industrial production, the continual evolution of machining techniques has actually paved the method for unprecedented accuracy and effectiveness in the production of bolts. Among the substantial developments in machining approaches is the use of Computer Numerical Control (CNC) innovation. CNC machines offer unequaled precision and repeatability by enabling automated control of machining tools. This specific control enables suppliers to develop facility and detailed fastener styles effortlessly.

Additionally, the adoption of multi-axis machining centers has allowed simultaneous cutting procedures from various angles, additionally enhancing effectiveness and minimizing production times. By using these advanced machining methods, suppliers can fulfill the enhancing demand for high-grade bolts while preserving cost-effectiveness in their procedures.

Selecting the Right Fastener Products

Picking the ideal material for fasteners is a vital choice that significantly impacts the efficiency and durability of the constructed components. When selecting the ideal bolt material, numerous aspects should be considered to make sure the resilience and integrity of the final product. The product chosen should be compatible with the ecological problems the bolts will certainly be exposed to, such as temperature level variations, wetness degrees, and corrosive components.

Typical materials used for bolts include stainless steel, carbon titanium, aluminum, and steel, each offering distinct buildings that match various applications. Carbon steel is a cost-effective option ideal for lots of general-purpose applications.

Enhancing Accuracy in Machining

Attaining ideal precision in machining is important for making certain the top quality and performance of machined elements. Precision in machining describes the capability to continually generate parts within limited tolerances and with high accuracy. To boost accuracy in machining, manufacturers utilize a variety of advanced strategies and technologies. One secret approach is using Computer system Numerical Control (CNC) devices, which supply remarkable accuracy and repeatability compared to conventional manual machining techniques. CNC machines are programmable and can execute complex machining operations with minimal human treatment, resulting in higher accuracy degrees.

In addition to CNC machining, the use of advanced cutting tools and device owners can additionally substantially boost accuracy. her comment is here Top quality cutting devices with sophisticated finishings decrease friction and wear, leading to a lot more exact cuts and dimensional precision. Carrying out stringent high quality control steps throughout the machining process, such as normal examinations and calibration of tools, helps maintain regular precision levels. By this hyperlink focusing on accuracy in machining, makers can achieve superior item top quality, tighter tolerances, and boosted total performance of machined parts.

Best Practices for Bolt Setup

Precision in machining plays an important duty in ensuring the dependability and long life of bolt installations. One crucial aspect is the appropriate selection of bolts based on the certain application needs when it comes to finest methods for bolt setup. Using the appropriate type, dimension, and product of fastener is vital to ensure optimum performance and resilience. Fasteners and Machining. Additionally, it is paramount to adhere Read Full Report to producer standards and recommended torque worths during the setup procedure to stop under-tightening or over-tightening, which can result in early bolt failing.

Furthermore, guaranteeing that the fastener threads are clean and cost-free of debris before setup is essential to accomplishing a safe and reliable link. By adhering to these ideal methods, suppliers can optimize the integrity and performance of their bolt installments.

Final Thought

By picking the best fastener products and enhancing accuracy in machining, suppliers can achieve ideal results in their operations. In general, understanding the art of fasteners and machining entails constant development and adherence to ideal methods.

In the realm of industrial manufacturing, the continual advancement of machining approaches has actually led the means for unmatched accuracy and effectiveness in the production of bolts.Accuracy in machining plays an important duty in guaranteeing the dependability and long life of bolt installations. When it comes to finest methods for bolt installment, one vital facet is the proper choice of bolts based on the particular application needs. By choosing the best bolt materials and improving precision in machining, suppliers can attain ideal results in their procedures. In general, understanding the art of fasteners and machining includes constant advancement and adherence to best practices.